Waterwheels

At one time there might have been up to 3 waterwheels in a line, though it is not certain that they would all have worked at once. The upper wheel is a 'pitchback' wheel while the other two were both overshot. For many years it was believed that undershot wheels, whose power depends on the speed of the water, were the most efficient. However, accurate experiments carried out by the Leeds engineer John Smeaton in the 1750's showed that overshot wheels, which depend on the height through which the water falls while in the buckets of the wheel, were the most efficient. The overshot wheel became the most common type of wheel used in Britain

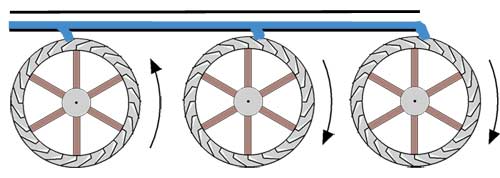

The water for an overshot wheel is brought over the top of the wheel to fall onto the wheel at a position of about 1 o'clock (looking at the wheel from outside the mill).

The pitchback wheel is an adaptation of the overshot in that the water falls on to the back of the top of the wheel at a position of about 11 o'clock rather than being taken over the top of it. This means that as viewed from outside the mill, the upper (pitchback) wheel will turn anti-clockwise, while the lower two (both overshot) would have turned clockwise.

Pitchback wheels have the advantage that the water flowing under the bottom of the wheel is moving in the same direction as the buckets as they turn. Therefore, they were often used in rivers that were prone to flooding; possibly here it was also because the headrace brings down a lot of debris from the surrounding woodland which could cause problems if it caught in the gap between the wheel and the head of the wheelpit. Their slight disadvantage is that the force of the water hitting the buckets can act against the motion of the wheel unless the water channel is carefully designed to prevent this by dropping the water vertically downwards.

The third wheel was interesting both in that it lay beyond the building and in that the power was taken from it by a toothed gear ring around its edge rather than through the axle as with the other two wheels. One of the original bearings is visible on the edge of the tailrace, and the bearing box for the gear that connected with it and took the drive into the building can be seen in the end wall of the mill. This third wheel is believed to have driven a sawbench and other machinery. The surviving photographs show its position, the ring gear and the gearwheels that engaged with it.