Development of the Current Watermill

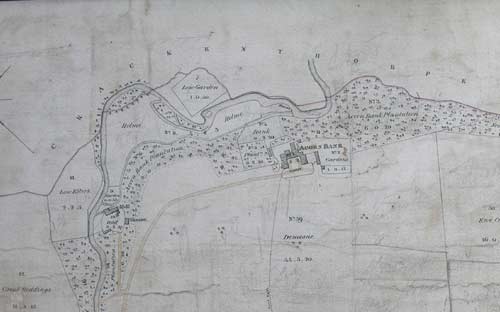

The first record confirming a mill on the current position comes from a map produced in 1744 by Thomas and Donaldson. It probably consisted of a single waterwheel driving a single set of stones.

Rate and Land Tax records show that the estate and mill were owned by a Mr R M Edmondson by 1790. Just three years earlier, in 1787, we also get second named 'milor', a Mr John Parker although there must have been others between him and Bell. At this point, it is still assumed that the mill consisted of a single waterwheel and milling stone, but that is soon to change. In 1823, the mill was rebuilt to become the building we see today. The work appears to have been undertaken by Mr A Edmondson; an inscription of his name and the date can be found on the ground floor wall of the mill. It is believed that the rebuild incorporated two waterwheels, each driving a single set of stones. The mill would have ground oats with one set of stones shelling the grain and the 2nd set grinding it. Oats were used to make clap bread and hasty pudding as well as providing animal fodder. Before they could be milled, they had to be dried, hence the need for the kiln room. Damp flour makes glue and the mill would have literally 'ground to a stop'.

It seems that the Edmondson's had leased the Acorn Bank Estate from the descendants of William Dalston. In 1824, William's granddaughter, Mary Hill, married John Boazman and shortly after they move into Acorn Bank. It's unknown as to what became of Mr A Edmondson.

By this stage, the mill complex had become quite large, as depicted on an estate map produced by Machell and Watson. The mill building appears much as it is today; there was also a bank barn, although smaller than the current one, on the opposite side of the courtyard to the mill. These two buildings appear joined by another small building, witness marks of which still remain on the mill wall. There was also the miller's house and pigsties, both still in-situ. The miller would have had a smallholding to grow his fruit and vegetables and it was common for millers to keep pigs; they were fed with the waste from the milling process. Records from 1838 show that the mill holding extended to 11½ acres.

By 1850, the estate was again leased out to a Mr Thomas Horrocks. His miller was Joseph Hutchinson, who was replaced by George Chester in 1865; George remained as miller for 20 years. At some point between 1850 and 1870, the mill is reconfigured to its current setup. Each of the 2 waterwheels now drive 2 sets of stones, 4 in total. This could indicate that the mill had changed from an undershot to overshot water supply. A set of French burr stones, which would provide higher quality flour, was installed, with the other 3 sets still using millstone grit. We continue to use these burr stones today to produce our flour today. A nameplate originally on them indicated they were made in Liverpool by 'Cotton and Davies' which dates them to pre-1853 although they may have come to Acorn Bank post-1853. The shrouds (cast iron rim) of the 2nd waterwheel were cast by 'Stalker Bros' of Penrith, a company only established in 1859 indicating that the redevelopment occurred after this.

Provincial corn mills started to acquire burr stones for milling wheat in 19th Century due to their superior quality. The introduction at Acorn Bank around the 1860s suggests that wheat was now being milled by at least one of the sets of stones. The other stones probably continued to mill oats both for those who preferred them (or couldn't afford wheat) and for animal feed.

Milling of wheat is likely to have been short-lived at Acorn Bank. Already, by the 1830s, industrial roller mills crushing corn through a series of large cast iron or steel rollers were being built. The pace quickened dramatically during the final quarter of the 19th Century and large mills such as Carrs of Silloth and Carlisle could produce wheat flour in huge quantity much cheaper than water mills. Unless it specifically states 'stone-ground', our modern flour will be ground in such mills.